Sven

Mücke

The Interdisciplinary Engineering Enthusiast

-

Graduating with a M.Sc. in Mechanical Engineering in Fall 2025

-

Spent 1 Year studying in the USA

-

4.5 Years in Formula Student

-

4.5 Years in an Industry Co-Op Program

-

Experience in Mechanical Design, Electrical Engineering & Mechatronics

Experiences & Projects during Master Studies

Master Thesis

“Optimal Microrobot Design for Ovarian Cancer Diagnostics”

Multi-Scale Robotics and Automation Lab | Purdue University | West Lafayette, Indiana | USA

1. Problem

Ovarian cancer is often diagnosed too late because standard imaging methods cannot reliably detect early‐stage tumors within the convoluted anatomy of the fallopian tubes.

2. Theory

The thesis builds upon the concept of untethered microrobots, specifically the tumbling magnetic microrobot (μTUM) platform developed at MSRAL. By leveraging controlled magnetic actuation, these robots can achieve targeted locomotion within confined biological structures. Combining knowledge of the female reproductive anatomy with prior microrobotic systems provides the theoretical foundation for optimizing design and performance.

3. Method

An initial literature review is conducted to understand current microrobotic applications, tumor biology, and anatomical constraints. Based on this, technical requirements are formulated and multiple concepts were evaluated using structured decision matrices. The most promising design is then modeled in CAD and validated through calculations of magnetic forces and torques. The prototype is fabricated via additive manufacturing (SLA/2PP), and its mobility and sampling capabilities are tested in various testing conditions. As the final stage, tests in a phantom model simulating the fallopian tube under varying magnetic field conditions are strived for.

4. Results

Coming soon!

Research Thesis

“Detection of Tooth Flank Damages in Planetary Gearboxes using Machine Learning”

Institute of Machine Elements | University of Stuttgart | Stuttgart | Baden-Wuerttemberg | Germany

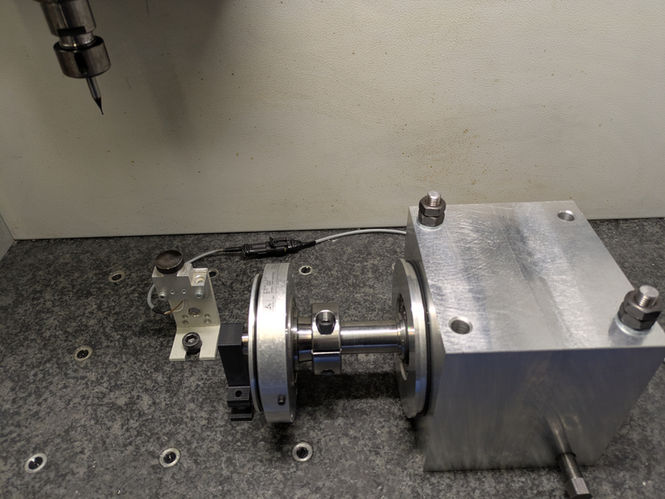

3. Method

A planetary gearbox (WITTENSTEIN) was instrumented with three vibration sensors and four temperature sensors. Synthetic pittings of four different sizes were created using CNC milling based on reverse-engineered gear geometries. To ensure consistent oil viscosity during tests, preliminary trials were conducted to control the gearbox temperature between 30 °C and 35 °C. The gearbox was then tested at 25 combinations of speed and torque for each damage size. A sparse autoencoder was trained on undamaged data and used to detect anomalies in subsequent measurements. The detection performance was compared across sensor positions and defect sizes.

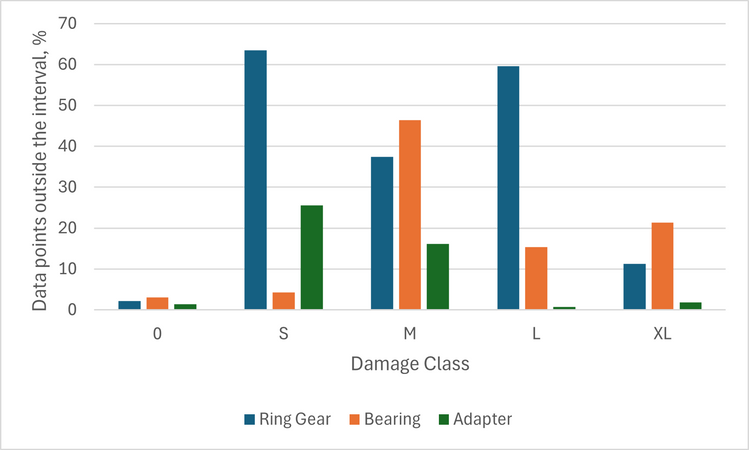

4. Result

The sparse autoencoder was able to detect tooth flank damages as small as 0.5% of the active surface area. The sensor mounted on the ring gear yielded the most reliable detection across various operating conditions, although in specific cases the bearing-mounted sensor outperformed it. Damage detectability was highest at low speeds and torques. The results confirm the suitability of machine learning for robust fault detection and provide insight into optimal sensor placement and test conditions.

1. Problem

Tooth flank damages such as pitting in planetary gearboxes can lead to severe mechanical failures if not detected early. Conventional condition monitoring often fails to reliably identify small-scale defects under varying operating conditions and are difficult to apply.

2. Theory

The thesis is based on the use of vibration-based condition monitoring combined with unsupervised machine learning techniques. Specifically, sparse autoencoders are employed to learn the normal behavior of the gearbox and detect deviations caused by emerging damages. The physical basis lies in the correlation between structural defects and characteristic vibration patterns measured by body-mounted sensors.

Mechatronics Projects

School of Engineering | The University of Kansas | Lawrence, Kansas | USA

RC Car Project

Problem

Developing a compact autonomous vehicle that can follow a line, avoid obstacles, and allow for remote control requires robust real-time processing and seamless integration of multiple sensors and actuators. Achieving this in a small interdisciplinary team presents additional coordination and interface challenges.

Solution

As part of a four-member international team, I was responsible for the software and electronics development. I created the circuit diagram using Fritzing and implemented the control logic in C++ using Visual Studio Code. The system included three infrared line sensors for course navigation and two ultrasonic sensors (one static and one mounted on a servo for rotation) for obstacle detection. These components were integrated on a microcontroller platform, enabling the vehicle to autonomously follow a line, detect and avoid obstacles, and respond to remote commands.

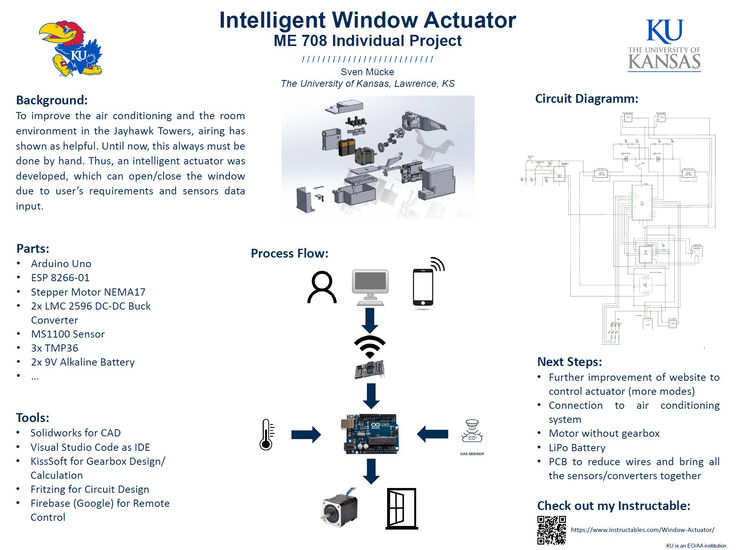

Window Opener

Problem

After completing the RC car project, we were challenged to independently develop a new mechatronics system using the knowledge and experience we had gained. I aimed to create a window actuator that could open and close a window both automatically and via remote control. This involved integrating mechanical design, electronics, software, and cloud connectivity.

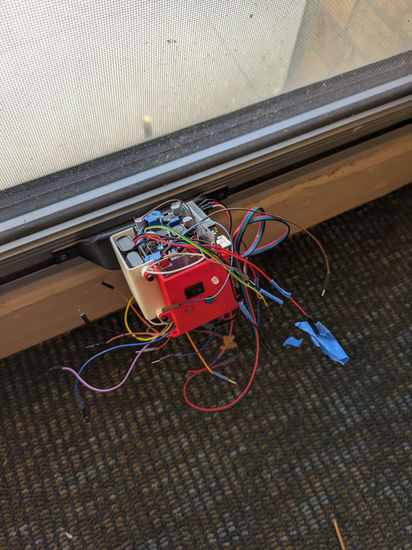

Solution

I developed a cloud-connected window actuator controlled by either sensor input or a mobile device. The system was built around an ESP8266 microcontroller, paired with an Arduino Uno. A stepper motor, in combination with a self-designed planetary gearbox (dimensioned in KISSsoft), was used to drive the window mechanism. I created the electrical schematics using Fritzing and implemented the control software in C++. Communication with Google Firebase enabled cloud-based control of the actuator.

Limitations

Although initial torque calculations indicated that the gearbox-motor combination would be sufficient, the battery failed to deliver enough electrical power to drive the system reliably. Additionally, due to time constraints, only a basic on/off toggle via Firebase was implemented for cloud control. Nevertheless, the project was a valuable hands-on learning experience —after all, as the saying goes: learning by doing.

Formula Student

Einstein Motorsport | Ulm | Baden-Wuerttemberg | Germany

Electric-Autonomous

CTO-Mechanics

-

Led the development of the team’s first electric-autonomous race car from initial concept to final rollout

-

Managed a 60-member interdisciplinary team and coordinated collaboration with over 40 industry partners

-

Oversaw the development of the wheel hub drive, including a high-speed HV-PMS motor (>20,000 rpm, 35 kW) and a lightweight 1.5-stage planetary gearbox

-

Designed the mechanical structure of a 600 V high-voltage battery system using lightweight materials, achieving a total weight of 49 kg (7.6 kWh)

-

Supervised key manufacturing processes such as CNC machining, welding, gear production, and SLS/SLM/FDM additive manufacturing

-

Contributed to competition success with 12th place overall at FS Croatia and 21st place at FS Germany (Overall: 32 & 64 competitors)

Subsystem Lead

-

Developed core concepts and technical specifications for the team’s first electric-autonomous race car in close collaboration with interdisciplinary subteams

-

Designed and integrated key mechanical assemblies and electromechanical interfaces, including the pedal box, suspension, and LV/HV packaging

-

Managed the full CAD model in Siemens NX, including the creation of parametric 3D models, technical drawings with GD&T, and complete BOMs

-

Led the design space coordination for the new carbon fiber monocoque, ensuring compatibility across mechanical and electrical systems

-

Designed and built an ergonomic test rig to validate cockpit geometry, driver interaction, and packaging constraints before composite layup

Combustion Engine

Team Lead Chassis

-

Led the development and manufacturing of a carbon fiber monocoque as head of a 10-member subteam, ensuring a lightweight and rigid chassis

-

Conducted mechanical calculations and physical tests (shear, bending, pull-out, crash) to meet safety and competition regulations (SES, SE3D, IAD)

-

Contributed to the team’s most successful season with 6th place at Formula Student Germany and 3rd place at Formula Student Spain (Overall: 60 & 30 competitors)

Team Member Chassis

• Assisted in the manufacturing of the chassis and the aerodynamic package

Cooperative Education Studies & Apprenticeship

Wieland-Werke AG | Ulm | Baden-Wuerttemberg | Germany

Cooperative Education Student

During my cooperative studies at Wieland, I gained hands-on experience across multiple departments, contributing to both operational and strategic projects:

-

Production & Manufacturing: Supported sheet metal fabrication, including production planning and internal order distribution

-

RD&I: Developed a key performance indicator to evaluate the success of a company-internal startup incubator

-

Process Engineering: Contributed to global digitalization efforts by assisting in the development of a stitch plan generator

-

Bachelor Thesis:

-

Merged seven data stores in Excel and KNIME to create an initial dataset with features and target variables describing stretch-bending process (with over 44,000 entries)

-

Applied clustering algorithms on dataset (Python) to classify operating conditions and derive 3400 manufacturing guidelines

-

Apprenticeship

Alongside my studies, I completed a certified apprenticeship as an industrial mechanic, giving me a solid technical foundation and hands-on experience in machining, maintenance, and manufacturing:

-

Technical Training: Gained experience in conventional and CNC machining, maintenance, and troubleshooting of energy infrastructure

-

Junior Company Leadership: Led a 6-member internal trainee company, managing company-internal manufacturing tasks

-

Cross-Departmental Rotations: Worked in various workshops including central maintenance and precision manufacturing, developing practical skills and organizational understanding

Education

Mechanical Engineering, Master of Science

University of Stuttgart | Stuttgart | Baden-Wuerttemberg | Germany

-

Specialization in Design Engineering/Product Development and Microsystems Technology

-

International Experiences:

-

Master Thesis

Multi-Scale Robotics and Automation Lab | Purdue University | West Lafayette, Indiana | USA -

Semester Abroad

Lectures in Mechatronics, FEA, Electronics, Biomechanics (Data Analysis)

School of Engineering | University of Kansas | Lawrence, Kansas | USA

-

-

Further:

-

International Buddy Program: ready.study.stuttgart

-

PROMOS Scholarship

-

Mechanical Engineering, Bachelor of Engineering

University of Applied Sciences Ulm | Ulm | Baden-Wuerttemberg | Germany

-

Specialization in Automation and Power Technology

-

Studied as "Ulmer Modell", comprised of 3 parts

-

Studies (Mechanical Engineering)

-

Apprenticeship (Industrial Mechanic)

-

Pracitical Training Phases (Wieland-Werke AG)

-

Industrial Mechanic, Journeyman

Chamber of Commerce and Industry / Robert-Bosch Schule Ulm

Ulm | Baden-Wuerttemberg | Germany

-

Specialization in Machining (CNC, Conventional) and Maintenance